computer-controlled cutting

fab academy week 3

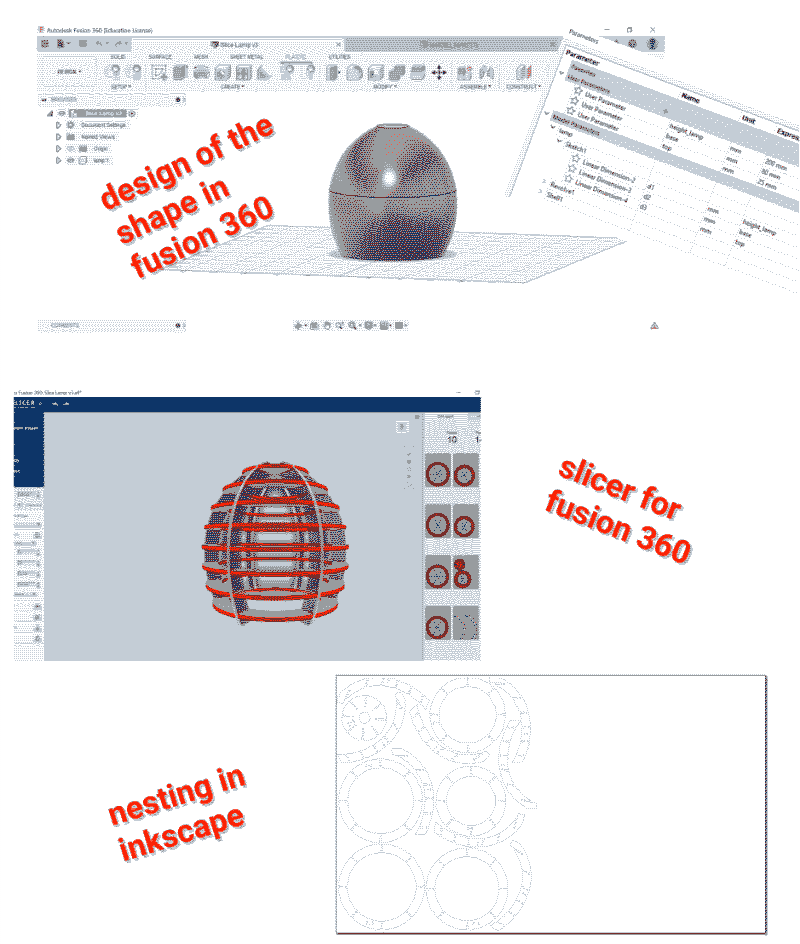

This week was took us to the next step after CAD with computer-controlled cutting class content here). The task we had was to create a design to design an object with parametric design tools.

To decide on the object I wanted to design, I hesitated between the different things I want to learn:

- Waffle technique using Slicer for Fusion

- Trying various types of joints in the same objects

- Mastering the kerf!

- Learning blender

After designing it, I can save it and open it in Slicer for Fusion 360 where I can change the parameters to have the slicing that I want. Before exporting it I need to also setup the material parameters to indicate the thickness of the material and the slot offset to take the kerf into account. I used MDF of 2.5 mm and indicated a kerf value of 0.1 mm.

The day I wanted to cut I only could book the small laser cutter so I reduced the number of slices in Slicer and reworked on the exported file in Inkscape to make a better nesting and only cut 2 boards of MDF instead of 4.

I like that the idea of minimizing the use of material with this nesting step and I was surprised in a good way that there are even nesting software that enable to do it. It reminds me of the arrangement of paper patterns on fabric when making clothes.

cutting

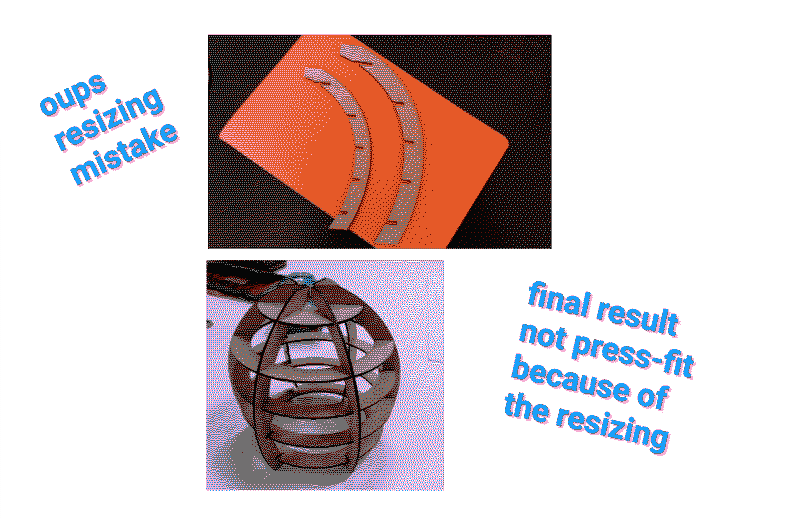

Santi helped me to cut the first MDF board, and after we printed a test, we realized the size was not right. The problem came from my export in Inkscape, by default it proposed me to export with “pt” unit and I had to change it to millimeters.As my booking was too short, we resized all the pieces directly in Rhino on the computer connected to the laster cutting machine. However we only had time to do it for one of the 2 board I had to cut. So I made another booking for the next day to continue the cutting! In the meantime I could resize and re-export the file from Inkscape.

Here I made another mistake! I resized the pieces one by one by applying a percentage but by mistake I resized one of the pieces twice! So my object cannot be completely assembled!