remixing materials #1 & #2

January-February 2022

faculty: Lara Campos, Laura Freixas

week #1 reflections

facts, feelings, findings

We had two classes with Lara Campos. She presented us her work, where she explores a lot our interactions with materials on a sensorial and emotional point of view. Lara is also part of S_Biotica (a collective working on R&D, education and industry collaboration) and Remix el Barrio collective.

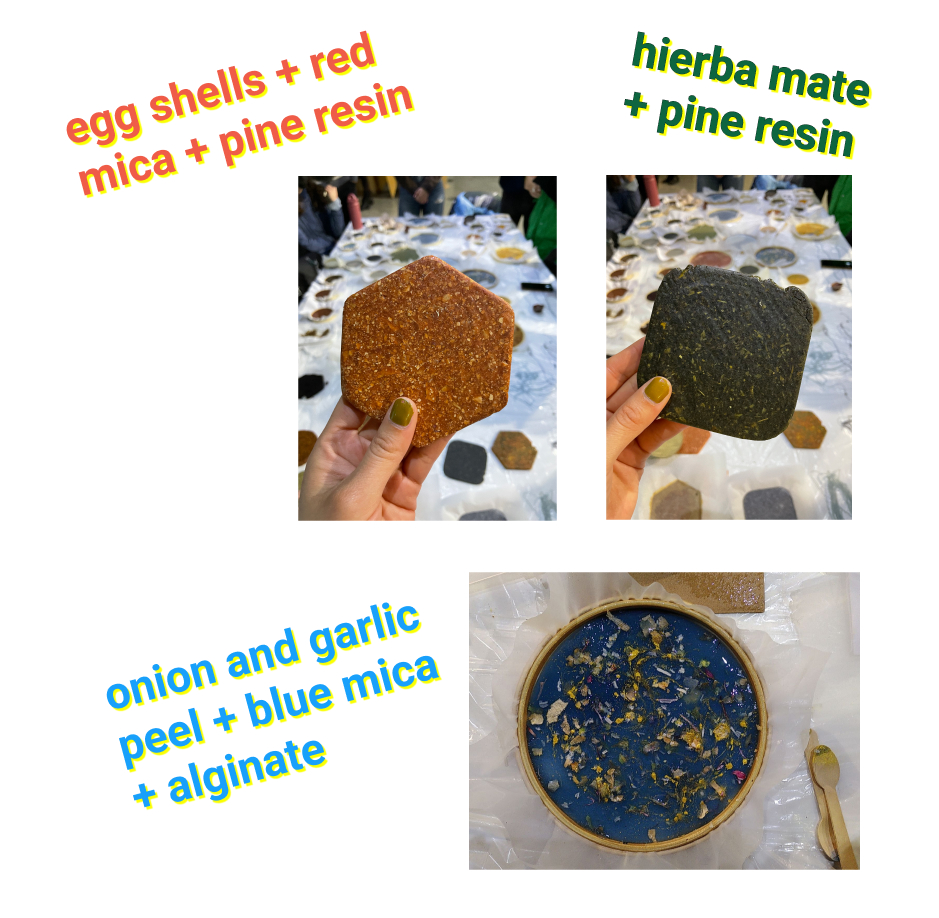

The first class was an introdution to the topic with a lot of inpiring examples of people or collectives working with biomaterials. And the second class was more hands-on, by groups, we experimented with 3 recipes using different biopolymers (agar, alginate, pine resin) and the waste we had brought. We experimented with different methodologies : flat surfaces, molds and extrusion.

Lara encouraged us to start engaging with stakeholders to gather the ‘waste’. I went to the coffee shop down my place and they were very happy to collaborate as they usually just throw away the coffee waste. They gave me a huge bag and said that I could come twice a week if I needed more.

However, I realized in class that I could not use it directly as it was still too wet and needed to be dried before making materials to avoid molding during the drying process. The different ways to dry/dehydrate materials are: in the sun if there is enough, or using the oven, open and a a very low temperature. I am not very in favour of the latest option which would consume a lot of energy. Another option would be to make or buy a dehydrator which we didn’t have a that moment. Julia is actually in the process of building one.

I didn’t know a lot about biomaterials before this week and I really appreciated the time we had for explorations with materials in reduced teams so everyone could really experiment. In general, I found the recipes were easy to follow with accessible ingredients and I could imagine myself trying a lot of different ones to find a good material, this is a process I quite enjoy.

future

There is so much potential to create materials with all the waste that surrounds us. Even if I knew food waste had a value, I mostly considered it in the angle of soil and compost. All the possibilities of creating materials out of it is completely new to my practice. I really appreciate the overall objective of this seminars to no think as material as something designers would just pick out of a catalog.

Despite that, below are some of the challenges I see to make the use of biomaterials more widespread.

words The word waste should be replaced by another to change the narrartive and make it appear as a resource. What would be appropriate?

question every material/ingredients Starting questionning the materials opens to even more questions. If I use pine resin as a biopolymer, how do I make sure it has been extracted respectfully? If we use mica powder to color biomaterials, how do we know it has not been collected in bad conditions (cf recent articles about child labour collecting mica)?

habits We need to collect A LOT of additives to mix to the biomaterials recipes. How to make that collection easy at home? How to do it at a larger scale with a community of neighboors for examples? Could we imagine that each building would have a place dedicated to collect : egg shells, vegetables and fruit peels, coffee waste...? And make sure that it is all dehydrated to avoid molding?

collaboration A lot of businesses in the city (restaurants, cafes...) produce waste daily without any way to reuse it. What systems could we design to ease that collection of unused material?

What would also have an important impact would be to collaborate with industries that create fossil fuel based plastic to replace it by bioplastics. What are the limits today to a more widespread use by industries?

logistics At a small scale it was easy to create our biomaterials this last week, however if we needed to scale it, there are a lot of logistics challenges to solve! How to transport the waste? Where to store it? How to be energy efficient in the drying process?

experimentations

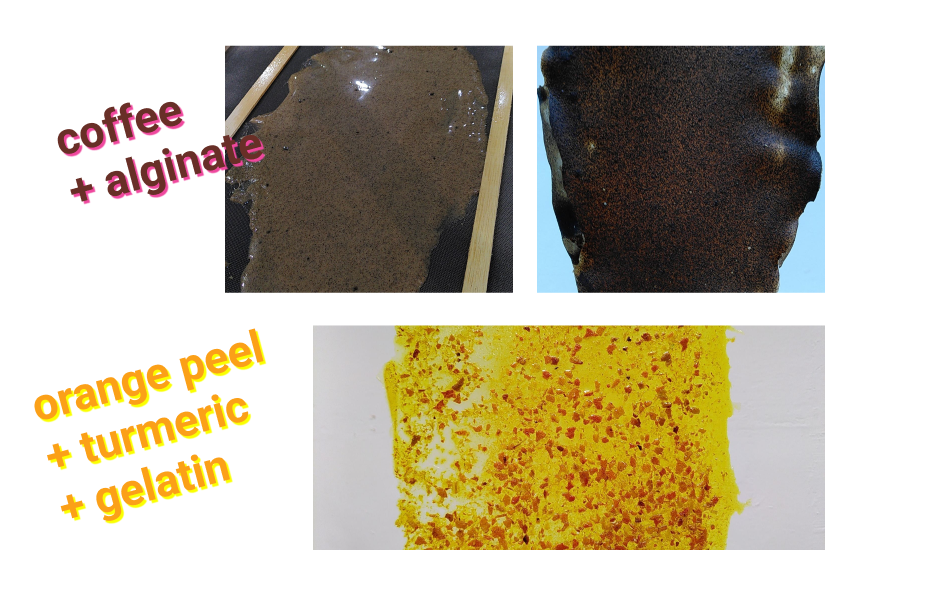

With Paula B. and Gerda, we continued exploring biomaterials fabrication after the course with the material available at IAAC and the waste we collected: coffee grains, orange peels, dried flowers.For coffee, I used a recipe of coffee composite that I found on Materiom. I multiplied the quantites by 10 to have a large piece of material that I would like to sew when it will be completelty dry. After one week, the result looks pretty dry and flexible, almost like a coffee leather!

I also wanted to make a material out of orange peels and used this Materiom recipe. After one week, it still seems sticky and might have too much glycerin!

week #2 reflections

factsFor the second part of Remixing materials seminar, the classes were held by Laura Freixas. She is a former MDEF student and her work was focused on creating relations between local producers, “waste resources”, designers and industries, her project is called “Organic Matters” and forms part of FabLab BCN project “Remix el Barrio” . The project Remix el Barrio was super inspiring with this approach of working at the scale of the neighborhoods.

This time, the class was even more focused on collaboration with the local ecosystem and we were invited to find actors/businesses in Poblenou with whom we could collaborate. With Paula, Gerda and Angel, after exploring different possibilities, we decided to collaborate with Freddo Fox, a brewery in Poblenou.

Here is a link to the board we created on Miro to start searching for inspiration of potential uses of this new resource.

We collected the beer spent grain that are left after brewing. Usually, they give it to farms to feed cattle but it is not enough and it implies the farmers have to come and collect it in Poblenou. They also have the option to give it to feed horses but this time the quantity is too much. We went twice and just collected 1-2 kilos each time.

Among the different options, we wanted to try to create paper with a technique similar to paper recycling techniques. We also tried to create a more solid material using pine resine and a wooden mold.

Below are the links to the documentation of our material exploration:

So far, the best results were with dried and ground beer spent grain. We recollected more grain at Freddo Fox to test variations of the recipe with the same base ingredients and variations : witout paper / with paper / with cardboard. We would also like to try it with the water used to cook rice to see the difference and maybe create a better binding. The results could be used as beer packaging if we imagine a collaboration with the brewery.

We would also like to try recipes of food using the spent grains, for this we need to organize precisely with the brewery to recollect the grain exactly the day they brew and not too late to avoid any fermentation.

learnings

More generally, after this whole seminar (part 1 and 2), I feel that we felt much more confident in starting to create materials, using existing recipes and also modifying them. I now look at all my food “waste” with a new eye and find myself curious about all sorts of materials, always trying to touch to have a first understanding of how they are made, how the could be made, how flexible or brittle they are...I notice that the different seminars start also “cross-pollinate”. In on of the fabacademy recent weekly tasks, we had to create a rendering of one of our designs, I never did that before so I had no idea what kind of “materials” were available in the program (Fusion 360 in my case) to apply to the created objects, and I was thinking it would be great to be able to select a biomaterial at this step. I sounds unimportant but I am sure it would contribute to make designers more aware of all the options of material we have.